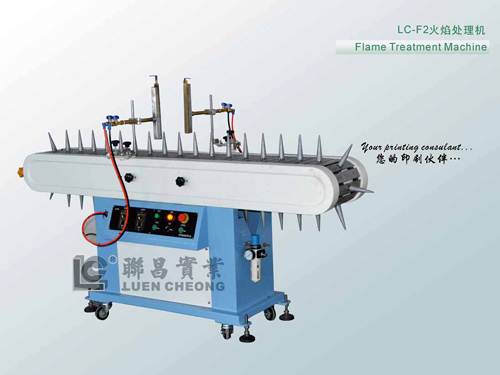

Applications:

Flame treatment PE or PP plastic surface of cosmetics, pharmaceuticals, food industry, such as: cosmetics bottles, detergent bottles, pen, etc., after the plastic products printing after the machine process, the ink can be more firmly adhered to by printed on the article.

Parameters:

1, according to the size of the print positioning portion, a tapered bearing replacement, to meet the needs of different sizes of prints.

2, conveyor belt part of the imported micro-speed motor, stepless adjustment of speed mode to suit different requirements of the workpiece.

3, fire-breathing head and advanced bus designs unique, high fuel efficiency, more energy efficient.

4, run fast, can reach 1200-3000 per hour, machine operation simple and easy to adjust, when the printing in contact flame will appear automatically turn bottle features that make the printing process more uniform and stable surface.

5, stainless steel sheet conveyor belt, aluminum cone, copper spark plugs more beautiful native apply.

6, the whole novel structure, reasonable design, easy operation, with movable casters, easy to move.

Technical Parameters:

Bottle diameter: 12-24 mm (standard)

Conveyor size: 2000 × 230 mm

Conveyor belt speed: 0-20 m / min

Adjustment: electronic stepless

Flame size: 25 ~ 250mm

Flame processor Fuel: LPG

Power: 220V / 50Hz

Pressure: 6 bar

Dimensions: 2200 × 1200 × 700 mm

Body weight: 140 Kg