Applications:

Round container industry cosmetics, pharmaceuticals and food, such as toothpaste tubes, test tubes, pen, lipstick tubes, bottle caps, cream bottle, cosmetic tube.

Parameters:

1, designed for surface bronzing special circular substrates designed mainly applied to the hose, caps, cream bottles, tubes and other round products.

2, machine integrated synchronous feeding, surface flame treatment, automatic alignment and other functions.

3, the whole machine realization mechanical transmission, touch screen operation, easy to achieve human-computer dialogue.

4, the electronic sensors to achieve "no member not print," low pressure alarm automatic monitoring and other functions.

5, the servo optical fiber alignment system, enabling precise alignment of the article.

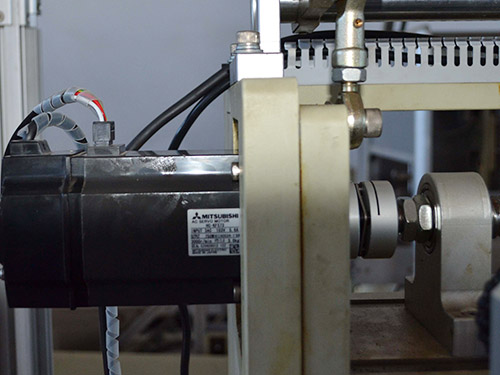

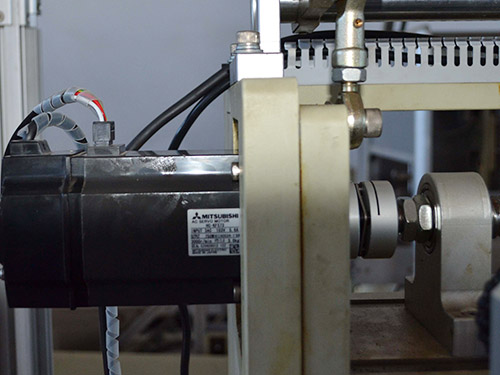

6, the whole machine electrical components and control systems used in Germany and Japan components, ensure that the machine is stable.

|

Project

|

Parameters

|

|

Maximum printing speed

|

3600 cycles / hour

|

|

Print area

|

236mm x 170mm (Φ75mm)

|

|

Be printed piece size

|

10mm <diameter <Φ50mm 20mm <height <120mm

|

|

Power Requirements

|

380V 50 MHz

|

|

Host volume

|

Approximately 1500mm x 1180 mm x 1900 mm

|

|

Weight

|

1000 Kg

|

|

Total power

|

4.5 KW

|

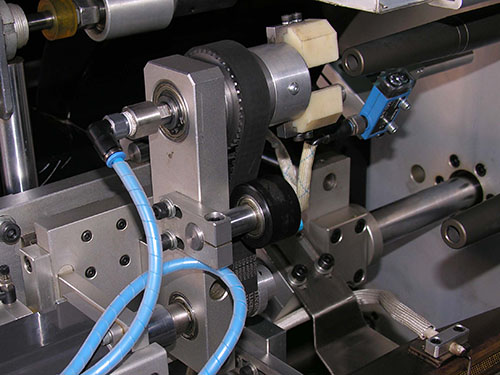

Online-servo system

Online-servo system

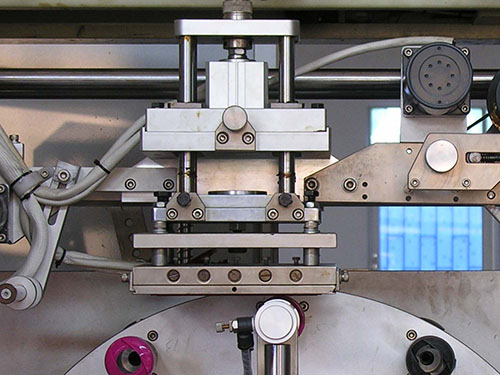

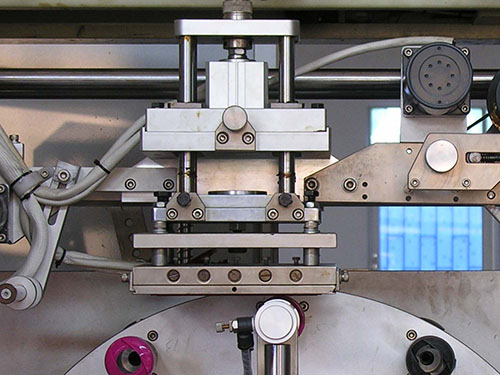

Stamping System

Stamping System

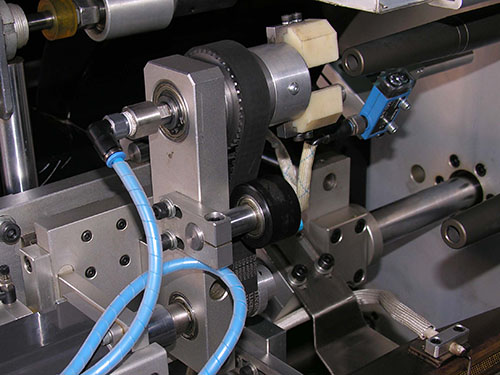

Rotational alignment system

Rotational alignment system